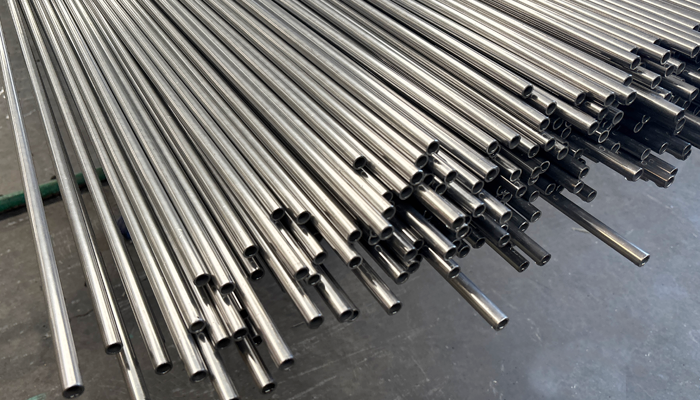

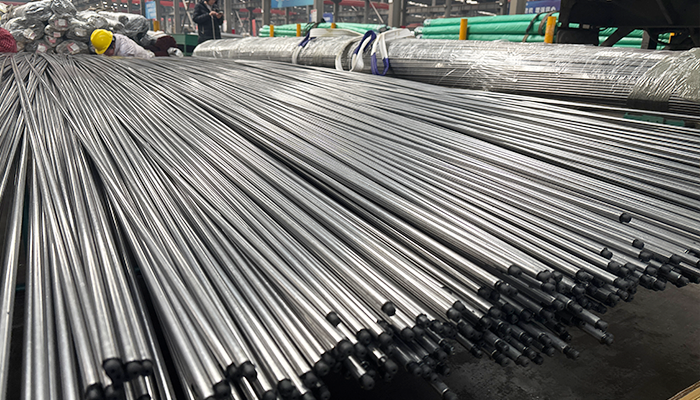

DIN 2391 ST 35 NBK Cold Drawn Seamless Steel Tube

Product Description

The DIN 2391 ST 35 NBK Cold Drawn Seamless Steel Tube is a high-quality steel tube designed for precision applications requiring seamless, cold-drawn processing. Made from ST 35 steel, it offers excellent strength, toughness, and durability, making it ideal for high-pressure and high-performance hydraulic systems. The NBK (annealed bright) surface finish enhances its corrosion resistance and surface quality, making it suitable for various industrial and automotive applications.

Product Advantages

Materials

- Steel Grade: ST 35

- Properties:

- ST 35: A low-carbon steel known for its good tensile strength and ductility.

- Excellent forming and welding capabilities, which are essential for high-precision applications.

International Standards

DIN 2391: Standard for precision seamless steel tubes used in hydraulic systems.

Dimension

Cold Drawn/Rolled Seamless Precision Steel Tubes Confirming To DIN2391;EN10305-1;EN10305-4

| OD | Thickness(mm) | ||||||||||

| mm | |||||||||||

| 6 | 6*1 | 6*1.5 | |||||||||

| 8 | 8*1 | 8*1.5 | 8*2 | ||||||||

| 10 | 10*1 | 10*1.5 | 10*2 | ||||||||

| 12 | 12*1 | 12*1.5 | 12*2 | 12*2.5 | |||||||

| 14 | 14*1 | 14*1.5 | 14*2 | 14*2.5 | 14*3 | ||||||

| 15 | 15*1 | 15*1.5 | 15*2 | 15*2.5 | 15*3 | ||||||

| 16 | 16*1 | 16*1.5 | 16*2 | 16*2.5 | 16*3 | ||||||

| 18 | 18*1.5 | 18*2 | 18*2.5 | 18*3 | 18*3.5 | 18*4 | |||||

| 20 | 20*1.5 | 20*2 | 20*2.5 | 20*3 | 20*3.5 | 20*4 | |||||

| 22 | 22*1.5 | 22*2 | 22*2.5 | 22*3 | 22*3.5 | 22*4 | |||||

| 25 | 25*2 | 25*2.5 | 25*3 | 25*3.5 | 25*4 | ||||||

| 28 | 28*2 | 28*2.5 | 28*3 | 28*3.5 | 28*4 | ||||||

| 30 | 30*2 | 30*2.5 | 30*3 | 30*3.5 | 30*4 | 30*4.5 | 30*5 | ||||

| 32 | 32*2 | 32*2.5 | 32*3 | 32*3.5 | 32*4 | 32*4.5 | 32*5 | ||||

| 34 | 34*2 | 34*2.5 | 34*3 | 34*3.5 | 34*4 | 34*4.5 | 34*5 | 34*6 | |||

| 35 | 35*2 | 35*2.5 | 35*3 | 35*3.5 | 35*4 | 35*4.5 | 35*5 | 35*6 | |||

| 38 | 38*2 | 38*2.5 | 38*3 | 38*3.5 | 38*4 | 38*4.5 | 38*5 | 38*6 | |||

| 40 | 40*2.5 | 40*3 | 40*3.5 | 40*4 | 40*4.5 | 40*5 | 40*6 | ||||

| 42 | 42*2.5 | 42*3 | 42*3.5 | 42*4 | 42*4.5 | 42*5 | 42*6 | ||||

| 45 | 45*2.5 | 45*3 | 45*3.5 | 45*4 | 45*4.5 | 45*5 | 45*6 | ||||

| 46 | 46*2.5 | 46*3 | 46*3.5 | 46*4 | 46*4.5 | 46*5 | 46*6 | ||||

| 48 | 48*2.5 | 48*3 | 48*3.5 | 48*4 | 48*4.5 | 48*5 | 48*6 | ||||

| 50 | 50*2.5 | 50*3 | 50*3.5 | 50*4 | 50*4.5 | 50*5 | 50*6 | ||||

| 54 | 54*3 | 54*3.5 | 54*4 | 54*4.5 | 54*5 | 54*6 | |||||

| 60 | 60*3 | 60*3.5 | 60*4 | 60*4.5 | 60*5 | 60*6 | 60*8 | ||||

| Note: 1. We can produce other specification as your requirements. 2. Surface treatment: Bright, galvanized (yellow, white, colorful), phosphated,army green passivation. |

|||||||||||

Features

- Seamless Construction: Made from a seamless tube, offering superior strength and uniformity compared to welded alternatives.

- Cold Drawn: The cold-drawing process improves dimensional accuracy, surface quality, and mechanical properties.

- NBK (Annealed Bright): This surface finish provides enhanced corrosion resistance, smoother surface finish, and improved mechanical properties.

- High Precision: Manufactured with strict tolerances to ensure a high level of precision, essential for hydraulic systems.

- Durability: Strong and durable, suitable for high-pressure and demanding applications.

Surface Finish

- NBK (Annealed Bright):

- Annealed brightprocessing provides a smooth, polished finish, enhancing both aesthetic appeal and functional resistance to corrosion.

- This surface finish reduces friction in hydraulic systems and extends the life of the components.

Specifications

| Specification | Details |

| Standard | DIN 2391 |

| Steel Grade | ST 35 |

| Surface Finish | NBK (Annealed Bright) |

| Application | Hydraulic, automotive, industrial |

Dimensions

| Outside Diameter (mm) | Wall Thickness (mm) | Length (m) |

| 6 – 100 | 1.0 – 10.0 | 6.0 (customizable) |

Production Process

- Cold Drawing: The tube undergoes a cold-drawing process to improve its dimensional accuracy and mechanical properties, enhancing the tube’s strength and surface finish.

- Annealing (NBK): After cold drawing, the steel tube is annealed in a controlled process to relieve internal stresses, enhance ductility, and achieve the bright finish.

- Surface Treatment: The surface is further treated to remove any surface imperfections and improve resistance to corrosion and wear.

- Quality Control: Each tube undergoes rigorous quality control tests, including dimensional checks, pressure testing, and non-destructive testing (NDT), ensuring compliance with international standards.

Applications

- Hydraulic Systems: Ideal for high-pressure fluid transport, such as hydraulic cylinders, pumps, and valves.

- Automotive Industry: Used in the production of components requiring precision and high mechanical strength, including brake lines and steering systems.

- Industrial Machinery: Applied in various industrial machines and tools, such as injection molding machines and compressors.

- Energy and Manufacturing: Suitable for use in manufacturing equipment and machinery that operates under high pressure and requires precision parts.

Why Choose DIN 2391 ST 35 NBK Cold Drawn Seamless Steel Tube?

- High Precision: Cold-drawn manufacturing ensures tight tolerances and a superior surface finish, crucial for precision applications.

- Durable and Reliable: The seamless construction combined with the NBK finishmakes this tube ideal for long-term use in high-pressure and demanding environments.

- Wide Range of Applications: Perfect for hydraulic, automotive, and industrial machinery, providing flexibility across different sectors.