What is a precision steel tube?

Hot-dipped galvanized tubing is made by dipping a mild steel tube into molten zinc at high temperatures until it reaches its desired thickness and coating thickness. The process takes place while the tube is being rolled, which results in a consistent finish throughout the entire length of the pipe. Hot-dipped galvanized pipe has several advantages over electro-galvanized pipe — including greater corrosion resistance, better abrasion resistance, and tensile strength — but it’s also more expensive than electro-galvanized pipe because it requires more processing steps during manufacturing.

1. The benefits of precision steel tube

What are the advantages of steel tubes?

While there are many reasons why steel pipe is the best choice for your next project, there are five primary benefits to using them over other materials:

Durability. Steel pipes are much more durable than pipes or tubes made out of other materials. They can withstand temperature extremes and exposure to harsh chemicals that would cause other pipes to rust or degrade. In addition, they’re resistant to corrosion from water and other liquids, which means they’ll last longer than copper or plastic pipes.

Rust-Proof. There’s no need for a protective coating when you use steel pipes because they’re already corrosion-resistant! This means fewer maintenance costs and fewer headaches down the road when it comes time to repair or replace your steel pipe system. …

Easy Installation. Steel pipes can be installed quickly and easily using any number of methods including welding, threading or using glue compounds such as epoxy resin adhesives.

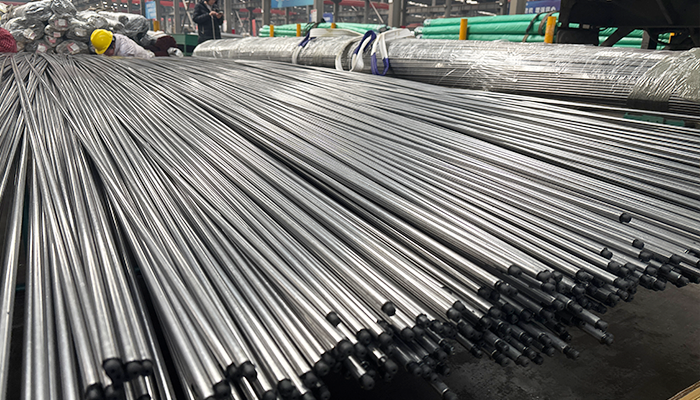

2. How are precision steel tubes made?

Tubular steel products are manufactured mainly by two different methods resulting in seamless pipes or in welded pipes. The starting material is always a hot steel billet. In the first case, the hot billet is processed by punching, hot rolling and stretch-reducing rolling into a seamless tube. This is followed by cold drawing to reduce its cross section to the diameter required for the finished product.

The second process is used for welded pipes, whereby the hot billet is processed by hot rolling and cold drawing to reduce its cross section to the diameter required for the finished product. It is then extruded with a mandrel through an electric arc furnace where it receives additional strength by means of welding.

All these processes are carried out on special machines which are designed according to the required dimensions and strength of the product that must be produced. The machines have been developed over many years and are constantly being improved so as to meet new requirements in terms of quality, productivity and costs of production.

3. The future of precision steel tube

Precision steel tubes are defined as a long hollow cylinders with an internal diameter less than its external diameter. These tubes are used in the manufacturing of various products such as aircraft, oil and gas, automotive and construction industries. The global precision steel tube market is expected to witness significant growth during the forecast period.

The global precision steel tube market has been segmented on the basis of product type, material type and end-use application. On the basis of product type, it has been segmented into round tubes, square tubes and rectangular tubes. In terms of material type, it has been segmented into carbon steel tube and stainless steel tube. On the basis of end use application, it has been segmented into the oil & gas industry, construction industry and automotive industry among others.

4. The History of Precision Steel Tube

The history of the precision tube dates back to the 1930s. At that time, the precision tube was mainly used in the manufacture of pneumatic parts and hydraulic components. It is said that the precision tube was first produced by the cold drawing process in Germany in 1933.

Precision tubes are carbon, alloy or stainless steel tubes with high precision dimensions. Usually it is made by hot rolling or cold drawing (cold rolling) process. Therefore, the precision tube is a kind of seamless tube.

Its design has several advantages:

No oxide coating on the inner and outer surfaces;

High pressure resistance, no leakage;

tight tolerances;

smooth surface;

No deformation in cold bending, no cracks in flaring test and flattening test. With these advantages, it is widely used in the manufacture of pneumatic parts and hydraulic components.

5. Manufacturing of Cold Drawn Precision Steel Tube

The department of cold-drawn precision steel tubes was formed in the year 1973, under the leadership of global-steeltube. The workshops were extended and new infrastructures were installed to produce cold-drawn precision welded tubes.

Among others the manufacturing of frames for the Talgo train and the Lube Motorbike.

Free Tube Sample.

Factory Directly Supply.

Reliable Quality With Reasonable Price

Regular Size No MOQ Required .