How to Choose Hydraulic Tube Materials: A Comprehensive Guide

-

2023-08-18

-

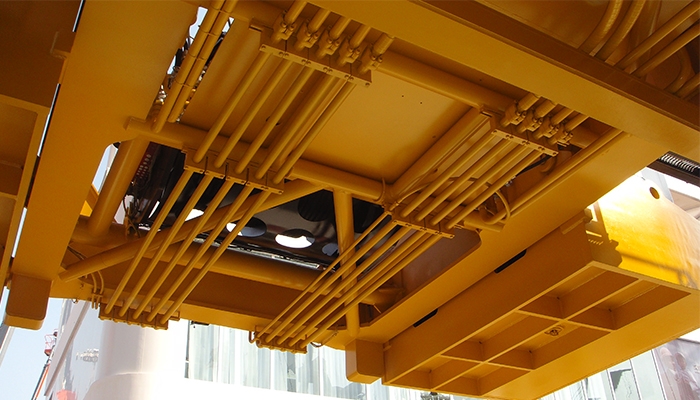

When it comes to hydraulic systems, choosing the right hydraulic tube materials for your tubing is of paramount importance. The tubing you select plays a crucial role in the efficiency, durability, and overall performance of your hydraulic system. Xuzhou Global Precision Steel Tube Co., Ltd understands the significance of this decision and offers a range of hydraulic tube materials, including carbon steel, stainless steel, galvanized steel, and copper tubes. In this comprehensive guide, we will delve into the factors you need to consider when choosing the ideal hydraulic tube material for your application.

Understanding the Basics: Why Tube Material Matters

The choice of hydraulic tube material impacts several critical aspects of your hydraulic system’s performance. These include corrosion resistance, pressure handling capabilities, temperature tolerance, and overall longevity. Different materials possess varying levels of these attributes, which is why selecting the right material is essential to ensure your hydraulic system’s reliability and efficiency.

Choose Hydraulic Tube Materials: Factors to Consider

1. Corrosion Resistance

Corrosion is a common concern in hydraulic systems due to the presence of fluids and potential exposure to environmental elements. Stainless steel and copper are known for their excellent corrosion resistance, making them suitable for applications where moisture or aggressive chemicals are present. Carbon steel tubes may require additional coatings or treatments to enhance their corrosion resistance.

2. Pressure Handling

The material’s ability to withstand high pressures is crucial in hydraulic systems. Stainless steel and carbon steel tubes are often preferred for high-pressure applications due to their robustness and structural integrity. Galvanized steel tubes, while providing good strength, might be better suited for moderate-pressure environments.

3. Temperature Tolerance

Hydraulic systems can experience a wide range of temperatures, from extremely cold to high heat. Stainless steel and copper exhibit superior temperature resistance compared to carbon steel, which can be vulnerable to extreme temperatures. The choice of material should align with the temperature conditions your system will face.

4. Fluid Compatibility

Different hydraulic fluids can have varying levels of compatibility with different materials. Stainless steel and copper have broad fluid compatibility, while galvanized steel and carbon steel tubes might not be suitable for certain aggressive fluids. It’s essential to consider the specific fluids your system will handle.

5. Application Environment

The environment in which your hydraulic system will operate plays a significant role in material selection. Outdoor and marine applications may require greater corrosion resistance, making stainless steel or copper tubes preferable. Indoor applications might have more flexibility in material choice.

Unveiling the Varieties: Steel, Stainless Steel, Galvanized Steel, and Copper

When it comes to hydraulic systems, the choice of hydraulic tube materials plays a pivotal role in ensuring reliability, efficiency, and longevity. Hydraulic tubes are the lifelines of these systems, transferring fluids and bearing the weight of complex operations. At Xuzhou Global Precision Steel Tube Co., Ltd, a reputable manufacturer, a wide array of hydraulic tube materials is available, each with its unique attributes. This article delves into the world of hydraulic tube materials, shedding light on the differences between carbon steel, stainless steel, galvanized steel, and copper tubes.

1. Carbon Steel Tubing: The Stalwart of Reliability

Carbon steel tubing is the backbone of many hydraulic systems due to its exceptional strength and cost-effectiveness. Its high tensile strength and good machinability make it suitable for heavy-duty applications. These tubes are well known for their durability and resistance to wear, making them ideal for withstanding the challenges of hydraulic fluid transportation. However, it’s important to note that carbon steel tubes may be susceptible to corrosion, particularly in demanding environments or when exposed to corrosive fluids.

2. Stainless Steel Tubing: Where Resilience Meets Corrosion Resistance

Stainless steel hydraulic tubing takes the durability factor up a notch by incorporating corrosion resistance. The addition of chromium in stainless steel provides a protective layer that prevents rust and corrosion, ensuring the integrity of the tube even in harsh conditions. This type of tubing is particularly suited for hydraulic systems where exposure to moisture, chemicals, or extreme temperatures is a concern. While stainless steel tubing offers enhanced resistance, it might come at a slightly higher cost compared to carbon steel.

3. Galvanized Steel Tubing: The Shield Against Corrosion

Galvanized steel tubing marries the robustness of carbon steel with an added layer of protection against corrosion. These tubes undergo a process where they are coated with a layer of zinc, creating a barrier that shields the underlying steel from rust and other corrosive elements. This makes galvanized steel tubing an excellent choice for hydraulic systems operating in outdoor or corrosive environments. The combination of strength, affordability, and corrosion resistance makes galvanized steel tubing a versatile option.

4. Copper Tube: The Conductor of Efficiency

Copper tubing stands out with its excellent thermal and electrical conductivity, making it a prime candidate for hydraulic systems that involve heat exchange or require efficient electrical grounding. Copper’s malleability and ductility facilitate easy bending and forming, reducing the need for complex fittings and connectors. However, copper’s relatively lower tensile strength compared to steel might limit its use in high-pressure hydraulic applications. Additionally, copper’s vulnerability to corrosion in certain environments should be carefully considered.

Conclusion

In conclusion, Xuzhou Global Precision Steel Tube Co., Ltd offers a diverse range of hydraulic tube materials to cater to a wide spectrum of applications. Carbon steel tubing provides reliability, stainless steel tubing adds corrosion resistance, galvanized steel tubing offers corrosion protection, and copper tubing excels in conductivity. By understanding the characteristics of each material and aligning them with the specific demands of the hydraulic system, engineers and designers can make informed choices that lead to optimal performance and longevity.

So, whether it’s strength, resilience, corrosion protection, or conductivity, there’s a hydraulic tube material that meets the needs of every hydraulic system, and Xuzhou Global Precision Steel Tube Co., Ltd is your reliable partner in acquiring these materials for your hydraulic applications.