Choosing The Right Diameter For Your Steel Hydraulic Pipes

-

2023-04-22

-

Steel hydraulic pipes are a critical component of many industrial applications. They provide reliable performance under heavy-duty conditions, withstanding high pressure and temperature.

However, choosing the right diameter for your steel hydraulic pipes is just as important as choosing the right material. The diameter of the pipe affects the flow rate, pressure, and efficiency of the hydraulic system.

In this blog post, we will discuss the importance of selecting the right diameter for your steel hydraulic pipes and the factors to consider when making this decision.

Factors To Consider When Choosing Diameter For Your Steel Hydraulic Pipes:

When selecting the diameter of your steel hydraulic pipes, it’s important to consider several factors. These include:

Flow Rate:

The flow rate is the volume of fluid that moves through the pipe per unit of time. A larger diameter pipe can accommodate a higher flow rate than a smaller one. If your hydraulic system requires high flow rates, you’ll need to choose a larger diameter pipe.

Pressure:

The pressure of the hydraulic system is another crucial factor to consider when choosing the diameter of your steel hydraulic pipes. A larger diameter pipe can handle higher pressure than a smaller one.

If your hydraulic system requires high pressure, you’ll need to choose a larger diameter pipe.

Velocity:

The velocity of the fluid through the pipe affects the pressure drop and energy loss in the system. If the fluid moves too quickly, it can cause damage to the pipes and other components. A larger diameter pipe can help reduce the velocity of the fluid, reducing energy loss and pressure drop.

Length:

The length of the pipe also affects the flow rate and pressure drop in the hydraulic system. A longer pipe will cause a greater pressure drop than a shorter one. If you have a long pipe run, you’ll need to choose a larger diameter pipe to maintain the desired flow rate and pressure.

Material:

The material of the pipe can affect the strength and durability of the hydraulic system. A larger diameter pipe made of stronger material can withstand higher pressure and provide greater durability than a smaller one.

How To Choose The Right Diameter For Your Business?

Once you have considered the above factors, you can determine the appropriate diameter for your steel hydraulic pipes. It’s important to choose a diameter that can handle the required flow rate and pressure of the hydraulic system without causing excessive energy loss or pressure drop.

A larger diameter pipe can accommodate higher flow rates and pressure, but it may also be more expensive and heavier than a smaller one.

In addition to the above factors, you should also consider the size and layout of your hydraulic system. The diameter of your steel hydraulic pipes should be compatible with the other components in your system, such as valves and pumps.

You should also consider any restrictions in the installation area, such as space limitations or weight limitations.

Here we recommend some steel hydraulic pipes from Global Precision Steel Tube for you, they are very suitable for hydraulic system applications.

For the Bright cold-drawn precision seamless steel tube DIN/EN:

- High precision and smooth surface:

This ensures the reliable performance of the hydraulic system, as the smooth surface allows for efficient fluid flow without obstruction or turbulence.

- No oxide layer and anti-rust on inside and outside:

This helps to prevent corrosion and rusting, prolonging the lifespan of the steel hydraulic pipes and ensuring the system operates smoothly for longer periods.

- Cold bending without deformation:

This allows for easy installation and maneuvering of the steel hydraulic pipes in various configurations, without the risk of deformation or damage to the pipes.

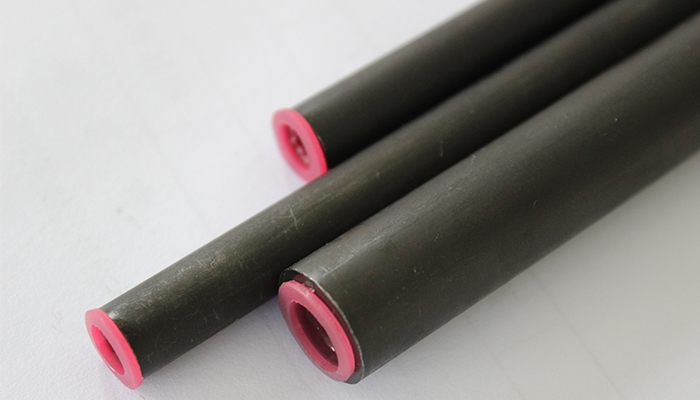

For the Black phosphated precision seamless steel tubes:

- High anti-corrosion and anti-rust:

This helps to prevent damage to the steel hydraulic pipes and ensures the reliable performance of the hydraulic system over time, even in harsh or corrosive environments.

- Good looking in appearance:

The uniform color and delicate phosphated coating make these steel hydraulic pipes aesthetically pleasing, and ideal for use in applications where appearance is important.

- Suitable for painting, and have strong adhesion:

This allows for further customization and protection of the steel hydraulic pipes, ensuring that they maintain their appearance and performance over time. The strong adhesion of the coating helps to ensure that the paint adheres properly and remains in place.

Examples Of Industries That Require Precise Diameter Selection:

The importance of selecting the right diameter for your steel hydraulic pipes is evident in many industries. Here are a few examples of industries that require precise diameter selection for their hydraulic systems:

Aerospace:

In the aerospace industry, hydraulic systems are used for controlling the movement of aircraft components. The diameter of the steel hydraulic pipes must be precise to ensure the system can handle the high pressure and temperature conditions of flight.

Construction:

In construction equipment, hydraulic systems are used to control the movement of heavy machinery. The diameter of the steel hydraulic pipes must be precise to ensure the system can handle the weight of the equipment and provide reliable performance.

Mining:

In mining operations, hydraulic systems are used to power machinery and transport materials. The diameter of the steel hydraulic pipes must be precise to ensure the system can handle the heavy-duty conditions of mining and provide reliable performance.

Final words:

Choosing the right diameter for your steel hydraulic pipes is crucial for the reliable and efficient operation of your hydraulic system. You should consider factors such as flow rate, pressure, velocity, length, and material when making this decision.

It’s important to choose a diameter that can handle the required flow rate and pressure of the hydraulic system without causing excessive energy loss or pressure drop.

If you want to make sure your choice is correct, or want more professional help, Global Precision Steel Tube is your best choice!