What Is Hydraulic Piping? – Essential Components For Industrial

-

2023-04-26

-

What is hydraulic piping? Hydraulic piping is a crucial component of industrial machinery and equipment, enabling the transfer of fluid power to various parts of the system.

It plays a vital role in the operation and maintenance of hydraulic systems and ensures optimal performance, efficiency, and safety.

In this blog, we will explore the essential components of hydraulic piping, the importance of hydraulic piping in industrial applications, and how to ensure proper maintenance and inspection of hydraulic piping systems.

What Is Hydraulic Piping?

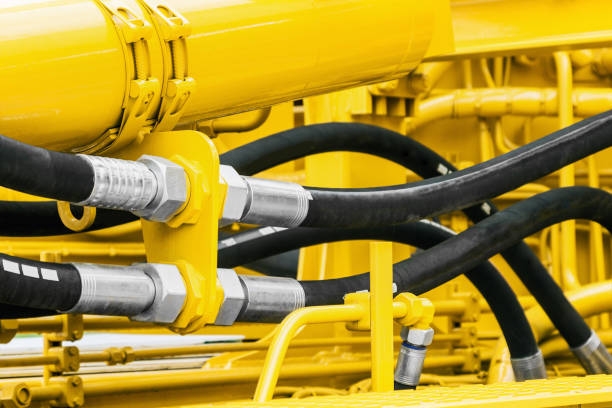

Hydraulic piping is a system of pipes, hoses, and fittings that transfer fluid power from one point to another in a hydraulic system. The hydraulic fluid is typically oil-based, and the hydraulic piping system provides a medium for the fluid to flow through the system and transfer energy.

Hydraulic piping is commonly used in industrial machinery and equipment, including manufacturing equipment, construction equipment, and automotive systems.

Types of Hydraulic Piping Materials:

The materials used for hydraulic piping depend on the specific application and the required level of pressure and temperature resistance. Some of the most common types of hydraulic piping materials include:

- Steel.

- Copper.

- Rubber.

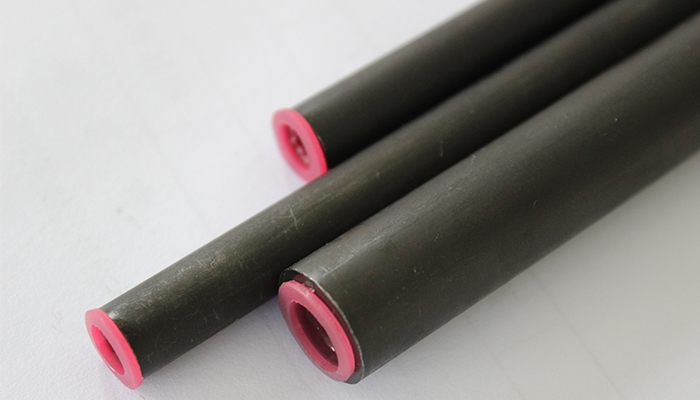

Here I recommend a company that specializes in providing high-quality phosphate precision seamless steel tubes: Global Precision Steel Tube. Taking its seamless steel pipe as an example, the following is a brief introduction to its steel pipe:

Global Precision Steel Tube’s DIN/EN black phosphated precision seamless steel tubes offer several advantages over other types of precision steel tubes. Here are three key benefits of using these tubes:

Excellent Corrosion Resistance

The black phosphated coating on both sides of the pipe provides high anti-corrosion and anti-rust properties. This makes them ideal for use in engineering machinery, ships, and other applications where exposure to harsh environments can cause rust and corrosion.

The phosphated coating also enhances the tube’s rust-prevention effect, ensuring long-lasting durability and reliability.

High Lubricity and Uniform Color

The phosphated coating on these precision seamless steel tubes provides delicate, high lubricity and uniform color. This ensures optimal performance and efficiency in hydraulic and pneumatic systems, where smooth and consistent fluid flow is critical.

The uniform color also provides a sleek and professional appearance, enhancing the overall look of the equipment.

Suitable for Painting and Strong Adhesion

The surface of the black phosphated precision seamless steel tubes is especially suitable for painting or spray treatment. The paint surface has strong adhesion, ensuring a long-lasting and durable finish. This makes these tubes ideal for precision machinery and other applications where appearance is important.

Additionally, the tubes’ high anti-corrosion and anti-rust properties make them suitable for use in outdoor environments, where exposure to the elements can cause rust and corrosion.

Essential Components of Hydraulic Piping:

Hydraulic piping consists of several essential components that work together to ensure proper fluid flow and energy transfer within the system. These components include:

Pipes and Tubes:

Pipes and tubes are the primary components of hydraulic piping systems. They are typically made of steel, copper, or plastic and are designed to withstand high pressures and temperatures. The size and thickness of the pipes and tubes depend on the application and the amount of fluid flow required.

Hoses and Fittings:

Hoses and fittings are used to connect the pipes and tubes in a hydraulic system. They are typically made of rubber or thermoplastic and are designed to withstand high pressures and temperatures. The fittings are used to connect the hoses and pipes and ensure a leak-free connection.

Valves:

Valves are used to control the flow of fluid in a hydraulic system. They are designed to open and close based on pressure changes in the system and are essential in regulating fluid flow and pressure.

Pumps:

Pumps are used to generate pressure and create fluid flow in a hydraulic system. They are typically powered by electric motors, internal combustion engines, or hydraulic motors and are critical in providing energy to the system.

Importance of Hydraulic Piping in Industrial Applications:

Hydraulic piping plays a vital role in the operation of industrial machinery and equipment. It enables the transfer of fluid power to various parts of the system and ensures optimal performance, efficiency, and safety.

Some of the key benefits of hydraulic piping in industrial applications include:

Increased Efficiency:

Hydraulic piping systems can transfer fluid power more efficiently than other types of systems. This results in faster operation and reduced downtime, which can increase productivity and reduce costs.

Enhanced Control:

Hydraulic piping systems provide better control over the operation of industrial machinery and equipment. Valves and pumps can be used to adjust fluid flow and pressure, allowing for precise control over the system.

Improved Safety:

Properly designed and maintained hydraulic piping systems are safer to operate than other types of systems. The use of high-quality components and regular inspection and maintenance can reduce the risk of equipment failure and accidents.

Greater Flexibility:

Hydraulic piping systems can be customized to meet the specific needs of industrial applications. The use of different materials, sizes, and fittings can be used to create a system that is tailored to the requirements of the equipment.

Ensuring Proper Maintenance and Inspection of Hydraulic Piping Systems:

Proper maintenance and inspection are essential to ensure the optimal performance and safety of hydraulic piping systems. Regular inspection and maintenance can identify potential issues before they lead to equipment failure or accidents, reducing downtime and costs.

Some of the key practices for ensuring proper maintenance and inspection of hydraulic piping systems include:

Regular Inspection:

Regular inspection of hydraulic piping systems is critical to identifying potential issues before they become major problems. Inspection should include checking for leaks, corrosion, and other signs of wear and tear.

Scheduled Maintenance:

Scheduled maintenance of hydraulic piping systems should be performed based on the manufacturer’s recommendations and the specific needs of the equipment. Maintenance activities may include replacing worn components, flushing the system, and checking fluid levels.

Use High-Quality Components:

The use of high-quality pipes, hoses, fittings, valves, and pumps is critical to the performance and safety of hydraulic piping systems. Using low-quality components can lead to premature wear and tear, leaks, and equipment failure.

Train Personnel:

Proper training of personnel is essential in ensuring the safe operation and maintenance of hydraulic piping systems. Personnel should be trained in the proper use and handling of hydraulic equipment, as well as the identification and resolution of potential issues.

Final words:

In conclusion, hydraulic piping is an essential component of industrial machinery and equipment, enabling the transfer of fluid power and ensuring optimal performance, efficiency, and safety.

It consists of several essential components, including pipes, tubes, hoses, fittings, valves, and pumps, that work together to provide energy transfer within the system.

Proper maintenance and inspection of hydraulic piping systems are critical to ensuring their optimal performance and safety. With regular inspection, maintenance, and the use of high-quality components, hydraulic piping systems can provide efficient and safe operation for industrial applications.