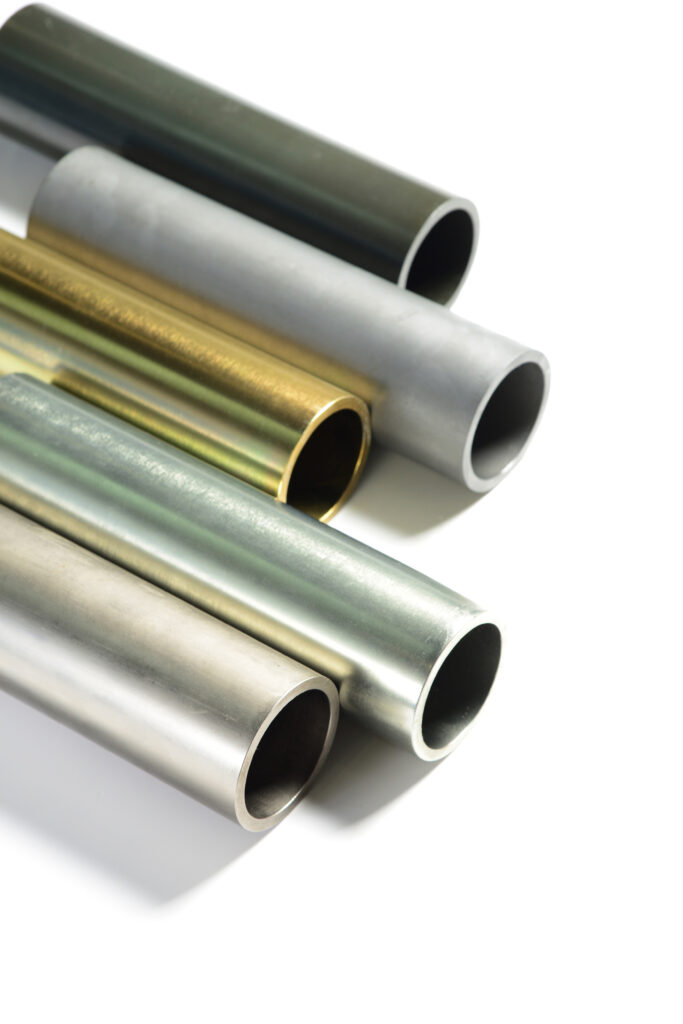

Carbon Steel Pipe – From a Manufacturer With Over 20 Years Experience

-

2022-09-07

-

Carbon steel pipe is an essential component in a broad range of industrial applications. We can use it for water and gas supply to oil and gas exploration, as well as in many other industries. It can be reinforced with either carbon or alloyed steel or both.

However, each type comes with its own unique properties that make it more suitable for certain applications than others. Let’s take a closer look at the properties of carbon vs alloyed steel pipe and see which one is right for you.

What Is Carbon Steel?

Carbon steel is an alloy with high carbon content. It is one of the most popular materials in the world, and its properties are the reason why. We can see it often in engineering because of its relatively cheap price, good strength, and resistance to corrosion.

There are two forms, either mild steel or high-strength steel (HSS). Mild steel is used in a variety of construction applications that don’t require high strength, such as handrails, steel railings, and flooring. It is also used in highly corrosive environments and has a lower corrosion resistance than high-strength steel.

HSS is used in any application that requires high strength, such as cranes, construction equipment, and offshore platforms. We apply it in applications where corrosion is a concern, as it has a higher corrosion resistance than mild steel.

What Is Alloy Steel?

Alloy steel is an alloy of iron combined with other metals. Alloy steel is most commonly used to refer to steels that contain both carbon and nickel, such as ASTM A53 and ASTM A 106. While these steels are not considered to be pure alloys, they are often referred to as such because of their high nickel content.

Carbon steel pipes with the same nickel content are referred to as nickel steels. Alloy steel pipes are further classified by their strength grade and yield strength: – Strength grade: The minimum yield strength represents the amount of force that the steel can withstand before it begins to deform elastically (bend).

When a material is stressed beyond its yield strength, it fails by cracking. – Yield strength: The minimum yield strength is the point at which material begins to deform plastically, meaning it loses its ability to return to its original shape after being deformed.

Properties Of Carbon Steel Pipe:

- Price:

The most cost-effective option for those looking to keep a project budget-friendly.

- Corrosion resistance:

We make them with a wide variety of coatings to provide additional corrosion protection.

- Strength:

They are very strong and can withstand high pressures and temperatures.

- Impact resistance:

However, they are not as impact-resistant as alloy steel pipes.

- Weldability:

It is easy to weld with its neutralized purity, making it easier to work with.

Properties Of Alloyed Steel Pipe:

- Price:

Alloy steels are more expensive than carbon steels, but they are also more corrosion-resistant.

- Corrosion resistance:

They are highly corrosion-resistant and suitable for use in a wide range of corrosive environments.

- Strength:

Alloy steel pipes are stronger than carbon steel pipes.

- Impact resistance:

There is higher impact resistance than carbon steel pipes but are not as impact-resistant as some other materials.

- Weldability:

Alloy steel pipes have a higher thermal conductivity than carbon steel, making them easier to weld.

Which Type of Steel Do You Have?

There are several ways to identify what type of steel you have, including using online carbon steel vs alloy steel calculator, a visual inspection, or a hardness test. For a visual inspection, take a look at the pipe’s surface.

If the surface appears smooth and slightly shiny, it’s most likely carbon steel. If the surface is rough and grey to black in colour, it is most likely alloy steel. Another way to determine the type of steel you have is by using a hardness test.

We can perform it by using a hardness testing machine, or by using an industrial hardness tester. A hardness test can help determine the carbon content of a piece of steel by taking a reading on its Brinell hardness number.

If the number is above 500, the steel is most likely carbon steel. If the number is below 500, the steel is likely alloy steel.

Pros And Cons Of Using Carbon Steel Pipe:

- Price:

Carbon steel pipes are the most cost-effective option.

- Corrosion resistance:

Carbon steel pipes are not very corrosion-resistant, which is why they are under the aegis of a protective layer.

- Strength:

They are typically not as strong as alloy steel pipes.

- Impact resistance:

Carbon steel pipes are not as impact-resistant as alloy steel pipes.

Pros And Cons Of Using Alloyed Steel Pipe:

- Price:

They are more expensive than carbon steel pipes.

- Corrosion resistance:

But they are highly corrosion-resistant and suitable for use in a wide range of corrosive environments.

- Strength:

Also, there is no doubt that they are stronger than carbon steel pipes, making them suitable for high-pressure applications.

- Impact resistance:

Alloy steel pipes have higher impact resistance than carbon steel pipes but are not as impact-resistant as some other materials.

Final Words – Which Type Of Steel Should You Use?

Carbon steel pipes are an excellent choice for mild, low-pressure applications, such as gas lines, handrails, and flooring. For high-pressure applications, such as water supply lines, you should use an alloy steel pipe.

If you are unsure which type of steel you have, you can use online carbon steel vs alloy steel calculator, a hardness test, or a visual inspection to determine the type of steel in your pipe and select the appropriate coating if needed.

Conclusion:

Welcome any inquiries related to the product: Global Steeltube.