Cutting Sleeve Hydraulic Seamless Steel Tube Assembly: A Better Solution

Product Name: Cutting Sleeve Hydraulic Seamless Steel Tube Assembly

Standard: EN10305-4 (DIN2445/2), EN10305-1 (DIN2391), ASTM A179

Steel grade: E235 (ST35 ST37.4), E355 (ST52 ST52.4)

Size: OD: 4-120mm, WT: 0.5-10mm, Length: Fixed 6m or as your request

Length: fixed 6m or as your request

Finish: 8 to 1 of this tube, there are 2

Delivery condition: +N (NBK) normalized under a controlled atmosphere

Delivery time: 15-45 days, according to the quantity you need and the item in stock

High Efficiency: Manufactured from high-strength alloy steel to ensure high wear resistance and sleeve durability

Simple operation: When your machine will shut down the pipeline by high-frequency vibration, it can be connected or driven through the port, end connection, or drive of the device to start the operation

Upper jaw plate: thickness is 0.4mm~0.8mm

Lower jaw: thickness is 0.4mm~0.8mm;

Hydraulic cylinder: high-quality cast iron cylinder head body, precision-machined valve chamber, thrust block bearing with multiple seals, to ensure its reliable operation in complex working environments;

If you have any questions, please contact us: global steeltube or qqt1@globaltube.cn

Product Advantages

-

Cutting sleeve

Cutting sleeve and nuts are imported from

-

Bending capacity

Maximum bending capacity: Φ 60*5mm

-

Cleanliness

Ultrasonic cleaning of inner and outer walls of steel pipes

-

High pressure

High pressure resistance, no leakage at connection points

-

Assemble

Easy to assemble and high efficiency

Work flow chart

Raw material–>Inspection chemical analysis, physical performance, sizes-

->Cutting–>Chamfer grinding (deburring)–>Pickling–>Saponifiation-

->Cold drawn / cold rolled–>Straightening–>Cleaning (Oil removal)-

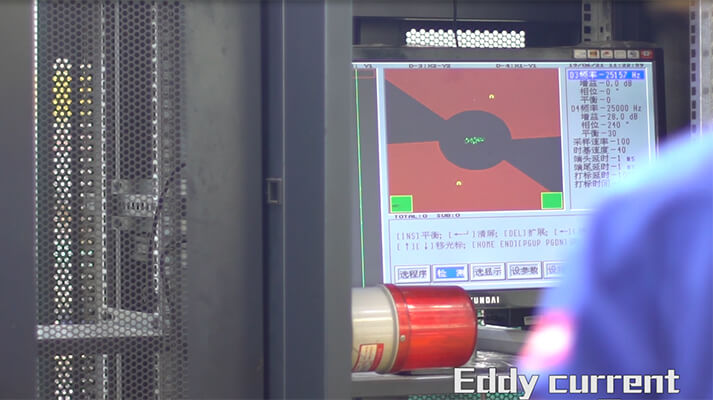

->Eddy current testing –>Anaerobic bright heat treatment (NBK)-

->Straightening–>Dimensional accuracy and surface testing-

->Eddy current testing–>Physical performance test–>Surface treatment (galvanized)-

->Cleaning and packaging–>Stock

| OD | Thickness(mm) | ||||||||||

| mm | |||||||||||

| 6 | 6*1 | 6*1.5 | 6*2 | ||||||||

| 8 | 8*1 | 8*1.5 | 8*2 | ||||||||

| 10 | 10*1 | 10*1.5 | 10*2 | ||||||||

| 12 | 12*1 | 12*1.5 | 12*2 | 12*2.5 | |||||||

| 14 | 14*1 | 14*1.5 | 14*2 | 14*2.5 | 14*3 | ||||||

| 15 | 15*1 | 15*1.5 | 15*2 | 15*2.5 | 15*3 | ||||||

| 10*1 | 16*1 | 16*1.5 | 16*2 | 16*2.5 | 16*3 | ||||||

| 18 | 18*1.5 | 18*2 | 18*2.5 | 18*3 | 18*3.5 | 18*4 | |||||

| 20 | 20*1.5 | 20*2 | 20*2.5 | 20*3 | 20*3.5 | 20*4 | |||||

| 22 | 22*1.5 | 22*2 | 22*2.5 | 22*3 | 22*3.5 | 22*4 | |||||

| 25 | 25*2 | 25*2.5 | 25*3 | 25*3.5 | 25*4 | ||||||

| 28 | 28*2 | 28*2.5 | 28*3 | 28*3.5 | 28*4 | ||||||

| 30 | 30*2 | 30*2.5 | 30*3 | 30*3.5 | 30*4 | 30*4.5 | 30*5 | ||||

| 32 | 32*2 | 32*2.5 | 32*3 | 32*3.5 | 32*4 | 32*4.5 | 32*5 | ||||

| 34 | 34*2 | 34*2.5 | 34*3 | 34*3.5 | 34*4 | 34*4.5 | 34*5 | 34*6 | |||

| 35 | 35*2 | 35*2.5 | 35*3 | 35*3.5 | 35*4 | 35*4.5 | 35*5 | 35*6 | |||

| 38 | 38*2 | 38*2.5 | 38*3 | 38*3.5 | 38*4 | 38*4.5 | 38*5 | 38*6 | |||

| 40 | 40*2.5 | 40*3 | 40*3.5 | 40*4 | 40*4.5 | 40*5 | 40*6 | ||||

| 42 | 42*2.5 | 42*3 | 42*3.5 | 42*4 | 42*4.5 | 42*5 | 42*6 | ||||

| 45 | 45*2.5 | 45*3 | 45*3.5 | 45*4 | 45*4.5 | 45*5 | 45*6 | ||||

| 46 | 46*2.5 | 46*3 | 46*3.5 | 46*4 | 46*4.5 | 46*5 | 46*6 | ||||

| 48 | 48*2.5 | 48*3 | 48*3.5 | 48*4 | 48*4.5 | 48*5 | 48*6 | ||||

| 50 | 50*2.5 | 50*3 | 50*3.5 | 50*4 | 50*4.5 | 50*5 | 50*6 | ||||

| 54 | 54*3 | 54*3.5 | 54*4 | 54*4.5 | 54*5 | 54*6 | |||||

| 60 | 60*3 | 60*3.5 | 60*4 | 60*4.5 | 60*5 | 60*6 | 60*8 | ||||

| Steel grade | C

max. |

Si

max. |

Mn

max. |

P

max. |

S

max. |

total

min. |

|

| Name | Number | ||||||

| E215 | 1.0212 | 0.10 | 0.05 | 0.7 | 0.025 | 0.015 | 0.025 |

| E235 | 1.0308 | 0.17 | 0.35 | 1.2 | 0.025 | 0.015 | — |

| E355 | 1.0580 | 0.22 | 0.55 | 1.6 | 0.025 | 0.015 | — |

| Outer Diameter | Allowable tolerance | Special tolerance | |||||

| GB/T3639 | DIN2391 | OD | WT | ||||

| 4mm-20mm | ±0.10mm | ±0.08mm | ±0.05mm | ±0.05mm | |||

| 20mm-30mm | ±0.10mm | ±0.08mm | ±0.08mm | ±0.08mm | |||

| 31mm-40mm | ±0.15mm | ±0.15mm | ±0.10mm | ±0.08mm | |||

| 41mm-60mm | ±0.20mm | ±0.20mm | ±0.15mm | ±0.15mm | |||

| 61mm-80mm | ±0.30mm | ±0.30mm | ±0.20mm | ±0.20mm | |||

| 81mm-120mm | ±0.45mm | ±0.45mm | ±0.30mm | ±0.30mm | |||

| Steel grade | Yield strengtha | Tensile strength | Elongation | ||||

| Name | Number | ReH | Rm | A | |||

| min. | min. | min. | |||||

| MPa | MPa | % | |||||

| E215 | 1.0212 | 215 | 290 to 430 | 30 | |||

| E235 | 1.0308 | 235 | 340 to 480 | 25 | |||

| E355 | 1.0580 | 355 | 490 to 630 | 22 | |||

FAQ:

1. What is a hydraulic pipe assembly?

Hydraulic components are made up of works of art and valves that are manufactured by them.

It also has accessories in its fittings and fittings. In this type of pipe fittings, the sub are connected by welding or pressing and their hydraulic pipe assemblies are used in many industries;

Commonly used in the automotive industry for hydraulic and other types of pipelines.

2. What is the purpose of the hydraulic pipe assembly?

Hydraulic components have many uses, but hydraulic systems need these systems for safe braking, but heavy duty braking systems to control the vehicle.

This means that they must be made of high-quality materials, such as stainless steel or aluminum, so that they do not get trapped in this high-pressure fluid.

Exposure to drinking water or substances on the road during use, and over time, other foods or foods found on it.

3. Do you offer payment plans?

Yes, we offer payment plans in various length options. View details of our payment plans.

4. How should I buy steel from you? How to choose the right one for me?

Yes, we offer payment plans in various length options. View details of our payment plans.

5. Can I get a sample?

Yes, please pay and freight before your samples. But you need to pay for samples and shipping by yourself.

6. How do you ship the goods by sea?

We usually ship to our factory by sea or air express (DHL UPS FedEx). Please let us know if our other way we ship to the factory. event. We also offer delivery service if required.

7. What are the payment terms?

For accepting large wire payments (by payment method), Western Union and we accept Alipay payments, but not for accepting small wire payments, only for secure wire payment purposes.

8. Who should I contact if I have any other questions?

If you have any questions, please contact us: global steeltube