How to Choose the Best Hydraulic Piping Supplier for Your Construction Project

-

2022-10-10

-

Construction projects can be complicated, but the difficulty is compounded when there are specialized processes involved. Hydraulic piping is one such process. It is a system that uses pressure instead of gravity to move fluids. In order to complete your construction project accurately and on time, it is important to find the right supplier for your needs.

When searching for a hydraulic piping supplier, you will want to make sure they provide quality products with fast turnaround times at an affordable price. The best way to do this is by keeping these three things in mind: product quality, price, and delivery timeframes. Let’s take a look at why these three things matter and how you can get the most out of your next hydraulic piping supplier.

What to Look for in a Hydraulic Piping Supplier

You want to find a supplier that meets all of your needs head-on. That means they should be able to deliver everything you need without any added hassle. If you have trouble finding a supplier that fits the bill, here are some things to consider.

- Product Quality

Let’s start with the most important factor. A supplier that has poor product quality is not worth your time. You need to choose a supplier that provides products that are both safe and reliable. You don’t want to deal with burst pipes or faulty connections that are not up to code.

- Price

You want to make sure you get a good price for your hydraulic pipes. It’s important to keep in mind, however, that you don’t want to sacrifice quality for a cheaper price. Always make sure the supplier you choose can give you the best bang for your buck.

- Delivery Timing

The last thing you want is to pay a lot of money for hydraulic piping, only to have to wait months for it to arrive. You want to make sure you find a supplier that can deliver your materials in a timely manner.

What Is The Function Of Hydraulic Pipes?

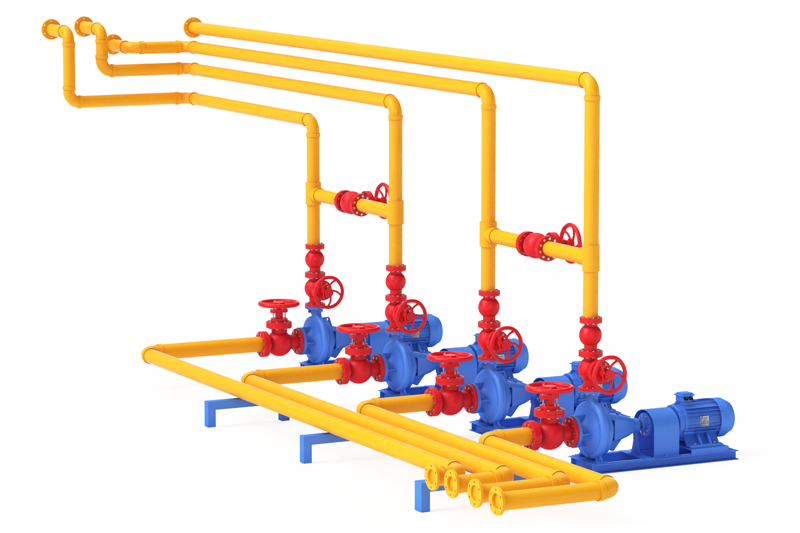

Hydraulic pipes are one of the main components of a hydraulic system. They transfer high-pressure fluids from one location to another. A hydraulic system uses pressure instead of gravity to move fluids. This is particularly useful for lifting heavy objects or moving objects that are too heavy for a manual system to lift.

Some examples of hydraulic systems include cranes, excavators, and mining equipment. Hydraulic pipes work by transferring fluid under high pressure. The fluid is moved through the pipe using a series of valves and pistons that build pressure. This pressure is then used to transfer the fluid to the next location. Hydraulic pipes can be used in any application that needs high-pressure fluid movement.

Can You Use Galvanized Pipe For Hydraulics?

Yes, you can use galvanized pipes for hydraulics. However, it is important to note that it is not the best option. Galvanized pipe is coated in zinc to protect against corrosion. Unfortunately, the zinc coating interferes with the function of hydraulic systems.

This is because the zinc coating interferes with the ability of hydraulic systems to transfer fluid. If you do choose to use galvanized piping for your hydraulic system, you can remove the zinc coating or use a different piping system altogether.

Product Quality

There are many factors that go into product quality. You can tell a lot about a supplier based on the quality of the goods they provide. Poor quality products can cause a number of issues, from decreased efficiency and performance to significant maintenance costs or repairs. You want to make sure you choose a supplier that provides high-quality hydraulic pipes.

Here are a few things to look for:

- Material

The first and most important thing to look for in quality hydraulic piping is the material. You want to make sure your supplier uses high-quality materials. This includes stainless steel or nickel-coated steel that is welded together with a seamless process.

- Dimensions

The dimensions of your pipes matter, too. You don’t want to end up with pipes that are too big or too small for your needs.

- Length

The length of your pipes matters, too. You want to make sure your supplier provides the exact length you need so you don’t have to make extra cuts.

Hydraulic Piping Supplier Price

It’s true that you get what you pay for. But the most expensive supplier is not always the best supplier for you. You need to make sure that you get a good price for your hydraulic piping without sacrificing quality.

Here are a few tips to make sure you get the best deal possible:

- Shop Around

It is important to shop around and get quotes from multiple suppliers. This way, you can make sure you are getting a good deal on the products you need.

- Negotiate

Most suppliers have a standard price. If you need more than a few pieces of plumbing, you can try negotiating for a lower price.

- Consider a Low-Cost Option

Some suppliers offer low-cost options for their products. This may not be the same quality as their standard products, but it can be a good way to save money on your project.

Delivery Timing

The last thing you want is to wait months for your hydraulic piping to arrive. This can throw your construction project off course, cost you precious time and end up being more expensive in the long run.

Here are a few things you can do to make sure you get your hydraulic piping on time:

- Find a local supplier

There’s no reason to order hydraulic piping from overseas. Find a local supplier that can get your pipes to you as soon as possible.

- Ask about shipping

Make sure you ask about shipping costs and if the supplier offers any discounts.

- Find a supplier with a good track record

Using a supplier with a good track record can help you avoid issues like delays or shipping problems. When you keep these three things in mind when choosing a hydraulic piping supplier, you can make sure you get everything you need for your project.