What You Need To Know Before Buying Automotive Steel Tubes

-

2022-10-08

2022-10-08

-

The automobile industry is one of the most competitive and demanding industries. There are stiff challenges to be overcome; any wrongdoing or substandard product launch can lead to a company going out of business. The auto industry continues to change and adapt, which is why innovation and new ideas are so critical for its success.

With the recent surge of new technology in autos, you might think that steel tubes are not as important for car production as they used to be. However, that couldn’t be further from the truth. Steel tubes remain an integral part of car manufacturing, with many different types being used throughout the process.

They provide strength and support for various parts of the car – from bumper bars to chassis components – which protects occupants during collisions and ensures their safety at all times.

What Is An Automotive Steel Tube?

Automotive steel tubes are specifically manufactured to meet the needs of the automobile industry. They are designed with precise specifications and use state-of-the-art technology to maximize their strength and longevity.

They are available in a wide range of diameters and wall thicknesses and can be customized to match the requirements of specific industries and applications. There are several different types of tubes used in the automobile industry, each with its own specific purpose. Some examples include tubes for chassis components, bumper bars, disc brake housings, and wheel arches.

Each of these tubes meets unique specifications, which vary depending on the specific application. A bumper bar tube is used for structural support in the front part of the car bumper. It is a steel tube that is bent in a “U” shape, with the ends folded over to form the bumper bar.

Chassis components, like floor rails and side rails, are critical for the structural integrity of a car, helping to support the weight of the engine and the passengers. Wheel arches are the parts of the car that cover the wheels. They can be made from either sheet steel or tube steel, depending on the design and manufacturer.

What Type Of Steel Is Used For Tubes?

If you are wondering what type of steel is used for tubes, the answer is – it depends on the application.

There are many different types of steel used in the production of tubes for applications in the automobile industry. The most common types are carbon steel and stainless steel, but certain types of tubes may be made from nickel alloy, copper alloys, and high-strength low-alloy steel.

- Carbon Steel

This is the most common type of steel used in the production of tubes for the auto industry. It is extremely durable and can withstand high temperatures, making it perfect for applications that require bending and flaring. Carbon steel is also relatively inexpensive, which is why manufacturers use it for many different types of tubes.

- Stainless Steel

This type of steel is highly resistant to corrosion and is therefore often used for tubes that come into contact with fluids. It is a relatively expensive material, which is why it is used only in circumstances where it is absolutely necessary. For instance, a tube that comes into contact with oil or fuel must be made from stainless steel.

- Nickel Alloy

This type of steel is used in the production of SS tubes for connecting rods, connecting rods being part of the car engine. The rod is the part of the engine that connects the crankshaft with the piston.

- Copper Alloys

These are alloys that contain copper as the main element. They are often used in the production of tubing for the fuel line.

- High-Strength Low Alloy Steel

This type of steel is used for the production of large-diameter tubing for crankshaft and connecting rod applications.

Automotive Steel Tubes For Tight Spaces And Tight Connections:

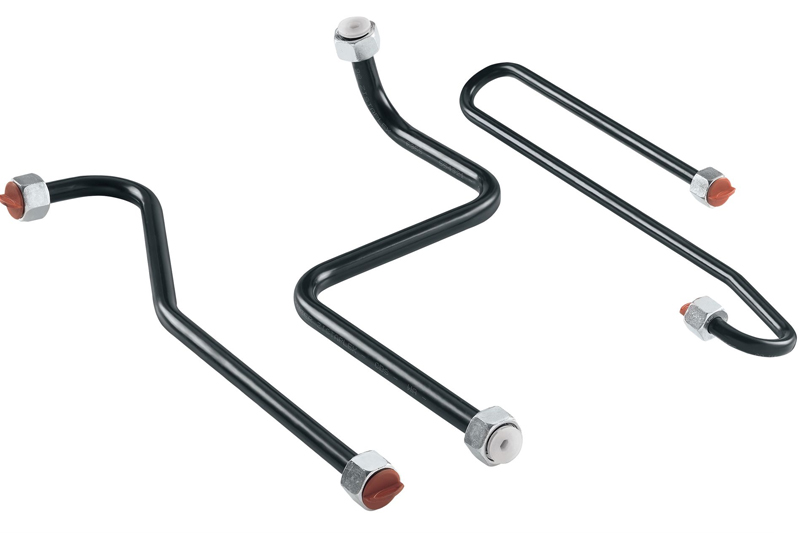

This type of tube is used when you need to deal with very tight spaces and tight connections. There are different types of tubes designed for different kinds of connections. For example, a T-shaped tube is used for a 90-degree elbow, and a C-shaped tube is used for a tee. A C-shaped tube is used to make a T-connection, and a T-shaped tube is used to make a C-connection. A Y-shaped tube is used for a branching connection, and a crossing connection can be made with a C-shaped tube. There are also types of tubes used for specific purposes, like gas conduits, vent tubes, and water tubes. Tubes for gas conduits have nozzles, and tubes for vent pipes have holes that lead to the outside of the car.

Automotive Steel Tubes For Optimal For Bending And Flaring:

These are specialized types of tubes that are designed for optimal bending and flaring. They are made up of thicker wall thicknesses and are thicker than normal tubes, making them perfect for these processes. There are several different types of tubes designed specifically for bending and flaring. A standard tube is used for everyday bending and flaring, a heavy wall tube is used for bending and flaring when you need a thicker wall than a standard tube, and a super heavy wall tube is used for extremely heavy bending and flaring applications.

Why Are Steel Tubes So Important For The Automobile Industry?

As stated above, steel tubes are used throughout the entire automobile manufacturing process. There are various types that are used in different areas, but they all have one thing in common – they are critical for the production process.

Steel tubes are critical because they provide support and strength for all of the different parts of the car. For example, they provide structural support for the engine, the transmission, and the suspension.

Without these steel tubes, the car would not be able to stand up to everyday wear and tear and would not be as safe for occupants as it is today.

- Bumper bars

The bumper bar is the strength behind the bumper of your car. It is what comes in contact with other vehicles when there is a collision. The bumper bar is made from a tube that is bent in a “U” shape, with the ends folded over to form the bumper bar.

- Chassis components

There are many different types of chassis components, each of which is made from tube steel to provide support for the car. The floor rail, the side rail, and the transmission tunnel are just a few examples of the many different chassis components that are made from tube steel.

- Wheel arches

The wheel arches are the parts of the car that cover the wheels. This part of the car is critical for protecting each wheel.

- Disc brake housings

These housings are critical for protecting the brakes on each wheel. They are made from tube steel, just like the wheel arches.

Conclusion of Automotive Steel Tubes:

There are many different types of steel tubes that are used in car manufacturing. Each is designed with a specific purpose in mind, and each is critical for the production process.

As the automobile industry continues to evolve, so do new innovations and new uses for steel tubes. Be sure to keep an eye out for these advancements, as they can provide added functionality to your car, which can be a deciding factor when purchasing a new model.