DIN 2391 Phosphated Precision Seamless Steel Tube

Product name: DIN 2391 phosphating precision seamless steel pipe

Standard: EN10305-4 (DIN2445/2), EN10305-1 (DIN2391), ASTM A179

Steel grade: E235 (ST35 ST37.4), E355 (ST52 ST52.4)

Size: OD: 4-120mm, WT: 0.5-10mm,

Length: fixed 6m or as your request

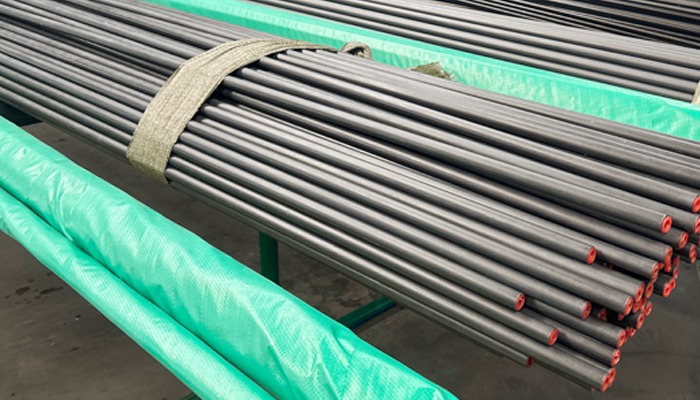

Surface Treatment: Phosphating–External Phosphating Coating

Delivery condition: +N (NBK) normalized under a controlled atmosphere

Delivery time: 15-45 days, according to the quantity you need and the item in stock

If you have any questions about product quality, usage, etc., please contact us: global steeltube

Product Advantages

-

Anti-rust

High anti corrosion & anti rust

-

Total phosphating

Phosphating inside and outside of steel pipe

-

Delicate

The phosphated coating is delicate, high lubricity, uniform color

-

Exterior

Good looking in appearance

-

Painting

Suitable for painting, and have strong

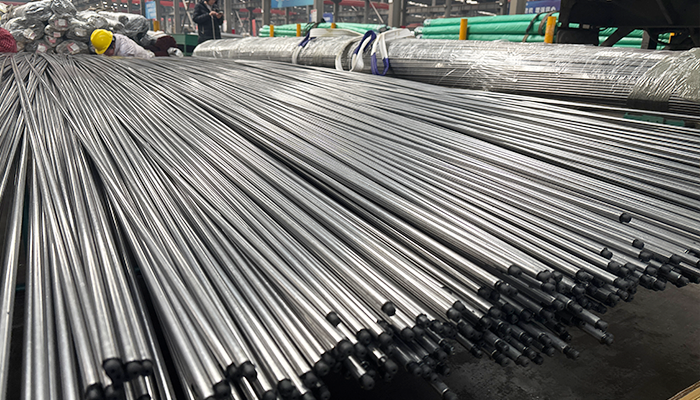

Cold drawn / cold rolled: High dimensional accuracy, excellent internal and external wall finish

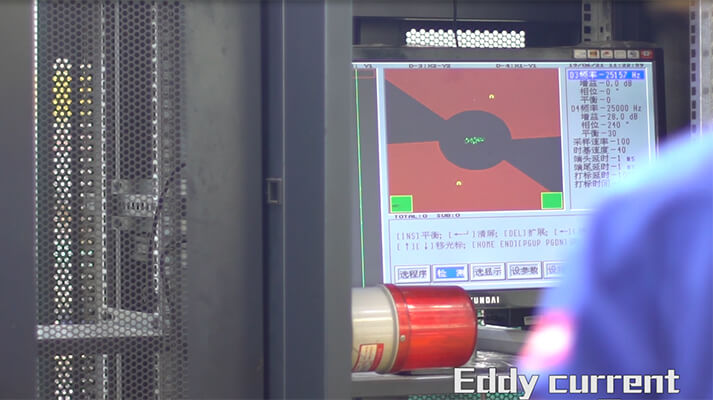

Eddy current testing: Each steel pipe is tested by eddy current flaw detection to ensure product quality

Anaerobic bright heat treatment (NBK): When the seamless steel pipe is annealed, vacuum is applied and ammonia-decomposed nitrogen and hydrogen are injected for protection heating, heat preservation and cooling. It maintains the original rolling accuracy and smoothness of the steel pipe, and has excellent mechanical properties and metallographic structure.

Surface treatment (phosphated): We perform high-quality phosphating treatment on the inner and outer walls of seamless steel pipes to form a uniform and dense crystal structure, which has strong corrosion resistance and porosity, and has strong coloring ability during painting and plastic spraying.

| OD | Thickness(m m) | ||||||||||

| mm | |||||||||||

| 6 | 6*1 | 6*1.5 | 6*2 | ||||||||

| 8 | 8*1 | 8*1.5 | 8*2 | ||||||||

| 10 | 10*1 | 10*1.5 | 10*2 | ||||||||

| 12 | 12*1 | 12*1.5 | 12*2 | 12*2.5 | |||||||

| 14 | 14*1 | 14*1.5 | 14*2 | 14*2.5 | 14*3 | ||||||

| 15 | 15*1 | 15*1.5 | 15*2 | 15*2.5 | 15*3 | ||||||

| 10*1 | 16*1 | 16*1.5 | 16*2 | 16*2.5 | 16*3 | ||||||

| 18 | 18*1.5 | 18*2 | 18*2.5 | 18*3 | 18*3.5 | 18*4 | |||||

| 20 | 20*1.5 | 20*2 | 20*2.5 | 20*3 | 20*3.5 | 20*4 | |||||

| 22 | 22*1.5 | 22*2 | 22*2.5 | 22*3 | 22*3.5 | 22*4 | |||||

| 25 | 25*2 | 25*2.5 | 25*3 | 25*3.5 | 25*4 | ||||||

| 28 | 28*2 | 28*2.5 | 28*3 | 28*3.5 | 28*4 | ||||||

| 30 | 30*2 | 30*2.5 | 30*3 | 30*3.5 | 30*4 | 30*4.5 | 30*5 | ||||

| 32 | 32*2 | 32*2.5 | 32*3 | 32*3.5 | 32*4 | 32*4.5 | 32*5 | ||||

| 34 | 34*2 | 34*2.5 | 34*3 | 34*3.5 | 34*4 | 34*4.5 | 34*5 | 34*6 | |||

| 35 | 35*2 | 35*2.5 | 35*3 | 35*3.5 | 35*4 | 35*4.5 | 35*5 | 35*6 | |||

| 38 | 38*2 | 38*2.5 | 38*3 | 38*3.5 | 38*4 | 38*4.5 | 38*5 | 38*6 | |||

| 40 | 40*2.5 | 40*3 | 40*3.5 | 40*4 | 40*4.5 | 40*5 | 40*6 | ||||

| 42 | 42*2.5 | 42*3 | 42*3.5 | 42*4 | 42*4.5 | 42*5 | 42*6 | ||||

| 45 | 45*2.5 | 45*3 | 45*3.5 | 45*4 | 45*4.5 | 45*5 | 45*6 | ||||

| 46 | 46*2.5 | 46*3 | 46*3.5 | 46*4 | 46*4.5 | 46*5 | 46*6 | ||||

| 48 | 48*2.5 | 48*3 | 48*3.5 | 48*4 | 48*4.5 | 48*5 | 48*6 | ||||

| 50 | 50*2.5 | 50*3 | 50*3.5 | 50*4 | 50*4.5 | 50*5 | 50*6 | ||||

| 54 | 54*3 | 54*3.5 | 54*4 | 54*4.5 | 54*5 | 54*6 | |||||

| 60 | 60*3 | 60*3.5 | 60*4 | 60*4.5 | 60*5 | 60*6 | 60*8 | ||||

| Steel grade |

C max. |

Si max. |

Mn max. |

P

max. |

S

max. |

Total min. |

|

| Name | Number | ||||||

| E215 | 1.0212 | 0.10 | 0.05 | 0.7 | 0.025 | 0.015 | 0.025 |

| E235 | 1.0308 | 0.17 | 0.35 | 1.2 | 0.025 | 0.015 | — |

| E355 | 1.0580 | 0.22 | 0.55 | 1.6 | 0.025 | 0.015 | — |

| Outer Diameter | Allowable tolerance | Special tolerance | |||||

| GB/T3639 | DIN2391 | OD | WT | ||||

| 4mm-20mm | ±0.10mm | ±0.08mm | ±0.05mm | ±0.05mm | |||

| 20mm-30mm | ±0.10mm | ±0.08mm | ±0.08mm | ±0.08mm | |||

| 31mm-40mm | ±0.15mm | ±0.15mm | ±0.10mm | ±0.08mm | |||

| 41mm-60mm | ±0.20mm | ±0.20mm | ±0.15mm | ±0.15mm | |||

| 61mm-80mm | ±0.30mm | ±0.30mm | ±0.20mm | ±0.20mm | |||

| 81mm-120mm | ±0.45mm | ±0.45mm | ±0.30mm | ±0.30mm | |||

| Steel grade | Yield strength | Tensile Strength | Elongation | ||||

| Name | Number | RH | Rm | A | |||

| min. | min. | min. | |||||

| MPa | MPa | % | |||||

| E215 | 1.0212 | 215 | 290 to 430 | 30 | |||

| E235 | 1.0308 | 235 | 340 to 480 | 25 | |||

| E355 | 1.0580 | 355 | 490 to 630 | 22 | |||

FAQ:

1. Can I get some samples?

Yes. We can provide samples, you need to pay the sample fee and shipping cost in advance. After you place the order, we will refund the sample fee. Please let us know your courier account or send us your fee and we will arrange to send you samples.

2. Can sample be produced?

Yes, we can make samples or technical drawings for you.

3. What are your payment terms?

Payment <= $1000, 100% prepayment. Payment >=$1000, 30% T/T in advance, balance before shipment. If you have other questions, please feel free to contact us.

4. What are your delivery terms?

EXW, FOB, CFR, CIF, DDU.

5. Can we visit your factory?

Warm welcome. Once we have your schedule, we will arrange for a professional sales team to follow up on your case.

6. If you have any questions, please consult: global steeltube