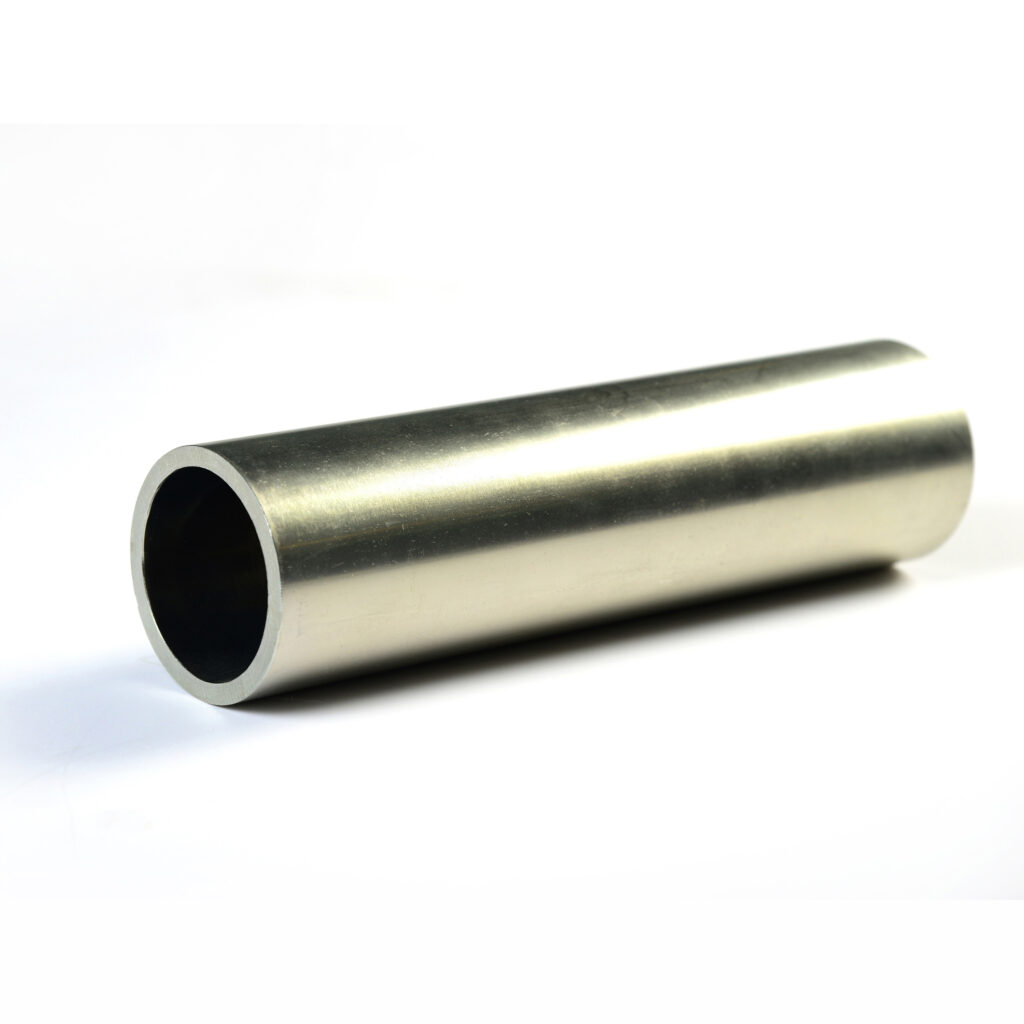

ASTM A106 Standard Painted Galvanized Water Pipe

-

2022-09-06

2022-09-06

-

The American Society for Testing and Materials (ASTM) is a globally authoritative resource for standards in materials, products, and services. For almost 140 years, the organization has provided manufacturers, businesses, and consumers with standards for goods across industries. The use of these standards helps to reduce the cost of goods and services by increasing efficiency and reducing variation from one product to another.

What is ASTM A106 Standard Painted Galvanized Water Pipe?

It is a kind of galvanized steel pipe that is produced by hot-dip galvanizing and carbon steel tubes. The specification for ASTM A106 Standard Painted Galvanized Water Pipe is in accordance with the standard of ASTM International.

Its mechanical properties of it are very good because the steel plate has been deformed by high temperature so it can ensure that there is no deformation during transportation or installation.

The chemical composition of ASTM A106 Standard Painted Galvanized Water Pipe includes: iron, chromium, silicon and manganese. The content of each element in ASTM A106 Standard Painted Galvanized Water Pipe is not less than 0.45%.

The surface layer of ASTM A106 Standard Painted Galvanized Water Pipe has a thickness of 0.25mm per meter or so; The thickness of the inner layer is between 50μm and 100μm; The thickness of the intermediate layer depends on the requirements set by customers. And the thickness of the core is between 20μm and 50μm.

The Main Advantages Of ASTM A106 Standard Painted Galvanized Water Pipe:

If you are looking for ASTM A106 Standard Painted Galvanized Water Pipe, we are here to provide the best quality products at competitive prices. With our years of experience, we have been able to offer you a wide range of ASTM A106 Standard Painted Galvanized Water Pipe.

We make use of the finest quality raw materials and the latest technology to manufacture these products. Quality is our top priority and so we ensure that each and every product we offer meets international standards. We are one of the most trusted manufacturers, exporters and suppliers of ASTM A106 Standard Painted Galvanized Water Pipe in India.

1. It has excellent corrosion resistance, which can assure you use it for a long time in a corrosive environment.

2. The surface of the pipe is smooth, bright and beautiful appearance, which is easy to clean and maintain.

3. The surface of the pipe has excellent anticorrosion performance in a wide temperature range, which can meet different requirements of products in different areas.

- This type of steel product is available in many grades and sizes according to customers’ needs.

- Good Corrosion Resistance

- Excellent For Longer Life Span

- Easy To Install And Maintain

- Anti-corrosion, anti-pressure, and anti-abrasion

- Easy installation

- Good economy

Application of ASTM A106 Standard Painted Galvanized Water Pipe:

1. In residential, commercial and industrial buildings and facilities to distribute water from the main to fixtures such as sinks, toilets, showers and faucets, have their figures to help function.

In addition to providing fresh water for use, water pipes also transport waste water away from fixtures, so that it can runs properly.

2. It is surely a kind of steel pipe with zinc coating on both inner and outer surfaces. It has played a great role in the construction industry for the transportation of water and other fluids under pressure.

3. It has low yield strength, but high tensile strength and good resilience after cold forming.

You can easily bend it through argon arc welding or electron beam welding according to the different thicknesses of the pipe, with proper preheating, we can use it as a structural part of various structures, and you can change the cross-section during construction without any operation.

There’re some other applications:

Heating systems;

Cold water supply systems;

Hot water supply systems;

Steam supply systems;

Oil supply systems;

Industrial boilers/heaters;

Sugar refineries/distillation towers/vapour condensers where corrosive chemicals are present;

Chemical processing plants where corrosive chemicals are present (e.g., nitric acid).

Precautions:

A painted galvanized water pipe is the most common type of water piping used in homes and residential buildings. We know that they are safe to use, but don’t forget to handle them carefully to avoid damage.

• Never bend or kink galvanized water pipe. It can easily crack or deform, which may result in a leaky pipe.

• Do not use a hammer to drive galvanized fittings into the ground. The fittings may break or crack due to shock waves created by the hammer strikes.

This kind of water pipe is a type of steel pipe coated with a thin layer of zinc. We usually use it for residential and commercial plumbing applications, as well as for certain types of industrial piping.

Galvanized water pipe does not rust, which means it won’t leak or corrode over time. It is also very durable and can withstand high pressure without bursting or leaking.

However, there are some precautions you should take when working with galvanized water pipes.

Inspect All Pipes Before Installation

When installing galvanized water pipes, always inspect them carefully to make sure they are free from defects. Galvanized water pipes come in coils that contain multiple pieces of pipe and may have defects due to incorrect manufacturing or damage during shipping.

You should look for any dents or kinks in the coils, which could indicate damage to the pipe during manufacturing or shipping. Also inspect the outside of the coil for signs of corrosion, which may indicate that the coating on the new pipe has been damaged during shipping or storage.

If you find any signs of damage on your new galvanized water pipes, contact your supplier immediately so they can replace them before installation begins.

Conclusion:

ASTM A106 is a specification for seamless steel pipes for high-temperature and high-pressure applications. The most common application for this standard is in the oil and gas industry, where we can use it to transport flammable liquids such as gasoline, diesel and jet fuel.

While ASTM A106 pipe has played a role in many different industries, its use in oil and gas production has made it one of the most widely used types of steel pipe worldwide.

ASTM A106 entered the criteria in 1966 by the American Society for Testing and Materials (ASTM). This organization is an international standards development organization that works with industry professionals to develop standards for all different types of materials and products.

The purpose of these standards is to create a universal set of guidelines that companies can follow when manufacturing their products or creating new processes or procedures.

The ASTM A106 standard is designed to improve the safety of flammable liquids transported through pipelines, ensuring they are made of high-quality materials that will not corrode or crack under pressure.

It also ensures that these pipes can have an inspection before they are used in any industrial application so that we can avoid any defects before they become dangerous leaks.

After reading this article, if you still have some questions, welcome to know more information, please contact us: Global Steeltube.