Choosing The Right Materials For Your Hydraulic Piping System

-

2023-04-19

2023-04-19

-

There are many different types of hydraulic piping systems that you may choose from when designing your system. It is important to choose the right materials for your hydraulic piping system so that it will be safe and reliable.

But do you know the answers to questions like how to pick the right material and what equipment you need? This blog will help you better understand this basic information.

Hydraulic Piping System Is Important For Industrial And Commercial Applications:

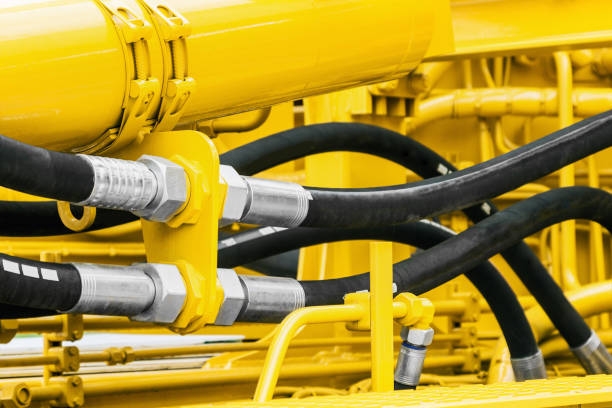

Hydraulic piping refers to a system of pipes or tubes used to transport hydraulic fluids, which are liquids or gases that transmit power in hydraulic systems. These fluids can be under high pressure and require a system that can handle these pressures without leaking or breaking.

Importance of Hydraulic Piping:

Hydraulic piping is essential in many industrial and commercial applications, such as construction, manufacturing, and mining. These systems are used to power heavy machinery and equipment, control processes, and operate vehicles. Without hydraulic piping, many of these applications would not be possible.

Efficient and Cost-Effective:

Hydraulic piping systems are an efficient and cost-effective way to transmit power and control processes. They can be designed to be compact and lightweight, allowing for easy installation and maintenance. They are also more energy-efficient than other types of systems, such as electrical systems.

Versatility:

Hydraulic piping systems are versatile and can be used in a wide range of applications. They can be used to power machinery, control processes, and operate vehicles. They can also be used in harsh environments, such as extreme temperatures, and are resistant to corrosion and wear.

Safety:

Hydraulic piping systems must be designed and installed in accordance with applicable codes and standards to prevent leaks, ruptures, and other failures. Proper maintenance and regular inspections are also necessary to ensure the safety and reliability of the system.

Hydraulic piping systems also require components such as fittings, valves, pumps, and hoses to ensure proper flow and pressure control. These components must be selected based on the system’s operating pressure, temperature, and fluid type to ensure optimal system performance and safety.

Additionally, hydraulic piping systems must be designed and installed in accordance with applicable codes and standards to prevent leaks, ruptures, and other failures.

Common Types Of Materials For Hydraulic Piping Systems:

When it comes to choosing the right materials for hydraulic piping systems, there are several common types of materials to consider:

- Carbon Steel:

This is one of the most widely used materials for hydraulic piping systems because of its high strength and durability. Carbon steel is also relatively inexpensive compared to other materials.

- Stainless Steel:

Stainless steel is highly resistant to corrosion and is a popular choice for hydraulic piping systems where corrosion is a concern. It’s also strong and durable, making it a great choice for applications where the system is subject to high pressure.

- Brass:

Brass is a softer material compared to carbon or stainless steel, but it has excellent corrosion resistance properties. It’s often used in hydraulic piping systems for water or other non-corrosive fluids.

- Copper:

Copper is a highly flexible material that can be used in hydraulic piping systems that require a high degree of flexibility. It’s also resistant to corrosion and has excellent thermal conductivity properties.

Factors To Consider When Choosing Materials For Hydraulic Piping Systems:

When selecting materials for hydraulic piping systems, there are several factors to consider to ensure optimal system performance and safety.

Pressure and Temperature Ratings:

Consider the maximum and minimum operating pressures and temperatures of the system and select materials that can handle these conditions.

Corrosion Resistance:

Consider the type of fluid used in the system and select materials that are resistant to its corrosive properties.

Mechanical Strength:

Select materials that have adequate mechanical strength to support the system’s weight and any other loads that may be placed on it.

Flexibility:

Choose materials that are flexible enough to accommodate any movements or vibrations that may occur in the system without breaking or cracking.

EN 10305 Galvanized Hydraulic Seamless Steel Tube:

The EN 10305 Galvanized Hydraulic Seamless Steel Tube is an excellent choice for hydraulic piping systems because of its high quality and durability. Here are some reasons why:

- Corrosion Resistance:

The tube is galvanized with a zinc coating of 8 to 12μm, providing excellent corrosion resistance and rust prevention.

- Mechanical Strength:

The tube is made from steel grade E235 (ST35 ST37.4), and E355 (ST52 ST52.4), which offers high mechanical strength and durability.

- Flexibility:

The tube is flexible enough to accommodate any movements or vibrations that may occur in the system without breaking or cracking.

- Surface Treatment:

The environmentally friendly electro-galvanized technology used in the tube’s surface treatment results in a uniform, dense, and well-combined galvanized layer (over 12μm) that makes it extremely resistant to corrosion and rust.

- Manufacturing Process:

The EN 10305 Galvanized Hydraulic Seamless Steel Tube undergoes a thorough manufacturing process that includes perforation, pickling, phosphating, cold drawing, cold rolling, annealing, and anaerobic annealing. This ensures a high-quality product that is free from defects.

The Global Precision Steel Tube Company Is A Good Choice For Your Business:

The Global Precision Steel Tube Company is a reputable and reliable supplier of hydraulic piping systems. Here are some reasons why they are a good choice for your business:

High-Quality Products:

The Global Precision Steel Tube Company offers a wide range of high-quality products, including EN 10305 Galvanized Hydraulic Seamless Steel Tubes, that are manufactured to meet international standards and specifications. These products are designed to be durable, reliable, and efficient, making them an excellent choice for industrial and commercial applications.

Customization Options:

The Global Precision Steel Tube Company offers customization options for their products, allowing you to tailor their products to your specific needs and requirements. They can produce customized products that are made to your exact specifications, ensuring that you get the product that best fits your needs.

Final words:

In conclusion, when choosing materials for hydraulic piping systems, it’s essential to consider factors such as pressure and temperature ratings, corrosion resistance, mechanical strength, and flexibility.

The EN 10305 Galvanized Hydraulic Seamless Steel Tube is an excellent choice for hydraulic piping systems because of its high quality and durability, as well as its resistance to corrosion and rust.