Custom Service & Best Solutions: Metal Hydraulic Lines

-

2023-09-15

2023-09-15

-

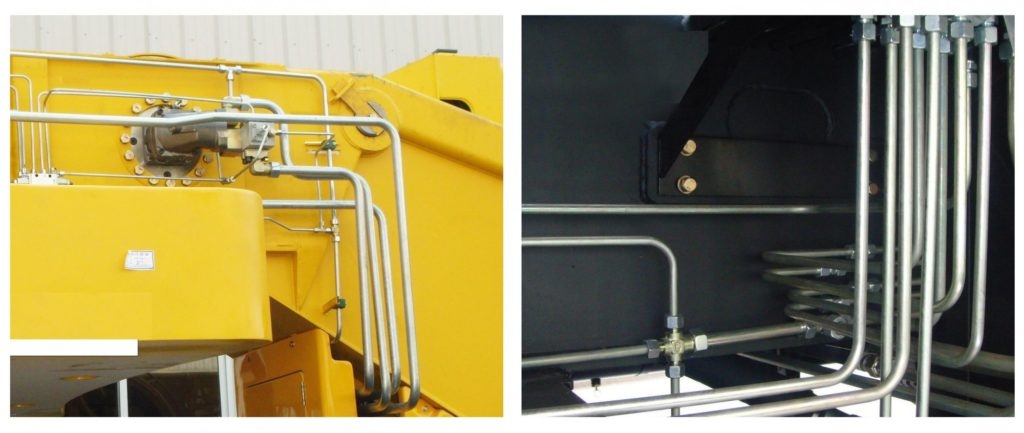

What are Metal Hydraulic Lines: Metal hydraulic lines are critical components in various industries, playing a pivotal role in transmitting hydraulic fluids and ensuring the smooth operation of machinery and systems. These lines are used to convey hydraulic oil or other fluids under high pressure to drive various hydraulic components, such as cylinders, pumps, and valves. When it comes to durability, reliability, and resistance to extreme conditions, metal hydraulic lines stand out as the preferred choice.

Applications of Metal Hydraulic Lines

Metal hydraulic lines are used in a wide range of applications across diverse industries, owing to their robust construction and high-performance capabilities. Some common applications include:

1. Automotive: In the automotive industry, metal hydraulic lines are crucial for powering brakes, steering systems, and suspension components.

2. Engineering Machinery: Heavy machinery relies on hydraulic systems to perform tasks like lifting, digging, and moving. Quality hydraulic lines are essential to maintain these operations efficiently.

3. Railway Locomotives: Modern rail transport systems depend on hydraulic systems to control brakes, doors, and even suspension in some cases.

4. Ships: In marine applications, hydraulic lines must be corrosion-resistant to withstand the harsh saltwater environment. They are used in steering systems, winches, and more.

Now that we’ve covered the basics, let’s delve deeper into selecting the right metal hydraulic lines for different applications.

Tutorials: How to Select the Right Metal Hydraulic Lines for Different Applications — Factors to Consider

Selecting the appropriate metal hydraulic line is essential to ensure optimal performance and safety. Here are some key factors to consider:

1. Material Composition: Metal Hydraulic Lines

Different metals offer varying levels of resistance to corrosion and high pressure. Common materials for hydraulic lines include stainless steel, carbon steel, and alloy steel.

2. Size and Diameter: Metal Hydraulic Lines

The size and diameter of the hydraulic line should match the flow requirements of the system. Smaller lines may restrict fluid flow, while larger lines can lead to inefficiencies.

3. Pressure Rating: Metal Hydraulic Lines

Determine the maximum pressure the hydraulic line will be exposed to. Ensure the chosen line has a pressure rating that exceeds this value for safety.

4. Flexibility: Metal Hydraulic Lines

Consider the application’s need for flexibility. Some applications require rigid lines, while others benefit from flexible hoses.

5. Temperature Range: Metal Hydraulic Lines

Take into account the operating temperature range of the hydraulic system. Ensure the chosen line can withstand extreme temperatures without compromising performance.

6. Environmental Conditions: Metal Hydraulic Lines

For applications in harsh environments, such as marine or corrosive industrial settings, opt for corrosion-resistant coatings or materials.

Now, let’s move on to maintenance tips to extend the lifespan of metal hydraulic lines.

Maintenance Tips: Caring for and Extending the Lifespan of Metal Hydraulic Lines

Proper maintenance is crucial to ensure the longevity and efficiency of metal hydraulic lines. Follow these essential maintenance tips:

1. Regular Inspections

Perform routine visual inspections to check for signs of wear, corrosion, or leaks. Address any issues promptly to prevent further damage.

2. Fluid Quality

Monitor the quality and cleanliness of the hydraulic fluid. Contaminated fluid can lead to damage to both the lines and hydraulic components.

3. Proper Installation

Ensure that the metal hydraulic lines are installed correctly, with appropriate fittings and connections. Improper installation can lead to leaks and pressure loss.

4. Avoid Overloading

Do not exceed the maximum pressure and load capacity specified for the hydraulic lines. Overloading can cause catastrophic failures.

5. Replace Aging Lines

Regularly assess the condition of metal hydraulic lines and replace any that show signs of deterioration or fatigue.

By following these maintenance tips, you can significantly prolong the life of your metal hydraulic lines and reduce the risk of unexpected failures.

Case Studies and Success Stories

Let’s take a look at some real-world examples of how customized metal hydraulic lines from Xuzhou Global Precision Steel Tube Co., Ltd have made a difference in various industries.

How Our Metal Hydraulic Lines Boosted Efficiency in an Automotive Assembly Line

In the highly competitive automotive industry, efficiency and precision are paramount. A leading automotive manufacturer faced challenges in their assembly line due to frequent hydraulic line failures. They turned to Xuzhou Global Precision Steel Tube Co., Ltd for a solution.

The team at Xuzhou Global Precision Steel Tube Co., Ltd collaborated closely with the client to design and manufacture custom metal hydraulic lines that precisely matched their requirements. These lines were crafted from high-strength stainless steel with a corrosion-resistant coating, ensuring durability and longevity.

The results were remarkable. The new metal hydraulic lines not only eliminated frequent line failures but also improved the overall efficiency of the assembly line. Downtime decreased significantly, leading to substantial cost savings and increased production output. The client’s satisfaction with Xuzhou Global Precision Steel Tube Co., Ltd’s customized tube solutions reinforced the company’s commitment to delivering excellence in the hydraulic industry.

Industry-Specific Content: Metal Hydraulic Lines

Now, let’s explore industry-specific content related to metal hydraulic lines.

1. Automotive: Trends in Hydraulic Systems

The automotive industry is continuously evolving, with a growing emphasis on electric and hybrid vehicles. Learn about the latest trends in hydraulic systems, including advancements in energy-efficient components and the role of metal hydraulic lines in this changing landscape.

2. Engineering Machinery: Challenges and Solutions

Heavy machinery faces unique challenges, from extreme loads to harsh environmental conditions. Discover how high-quality metal hydraulic lines can address these challenges and contribute to the reliability and productivity of heavy equipment.

3. Railway Locomotives: The Power of Hydraulics

Explore the crucial role of hydraulic systems in modern railway locomotives. From braking systems to suspension control, hydraulic lines play a vital part in ensuring passenger safety and smooth operation.

4. Ships: Corrosion-Resistant Hydraulics

In the marine industry, corrosion is a constant threat. Dive into the importance of corrosion-resistant metal hydraulic lines in maritime applications and their role in maintaining ship functionality.

5. Hydraulic Systems: Evolution and Future Trends

Finally, gain insights into the evolution of hydraulic systems and what the future holds for this technology. Learn how innovations in materials and design are shaping the hydraulic industry.

6. Product Spotlights

Stay informed about the latest innovations and unique selling points of Xuzhou Global Precision Steel Tube Co., Ltd’s metal hydraulic lines through our product spotlights. Watch videos and explore infographics to discover the features and benefits that set our products apart.

Conclusion

In conclusion, metal hydraulic lines are integral to the functioning of various industries, ensuring the smooth operation of hydraulic systems. By understanding their basics, selecting the right lines, and following proper maintenance procedures, you can maximize their lifespan and efficiency. Stay tuned for more industry insights and success stories from Xuzhou Global Precision Steel Tube Co., Ltd.